智能制造时代,数字化、智能化、物联化已成为全球各个产业趋之若鹜的发展方向,各个产业将从单纯的机械生产转换成数字化前沿智能终端

Digitalization, intelligence, and IoT have become the development direction pursued by global industries.

All industries are transforming from pure mechanical production to digital frontier intelligent terminals

模具产业也在同步趋向互联数字化生产解决方案的优势崭露头角,联泰科技联手汇锋鞋模带来了专业的鞋业3d模型行业数字化解决方案,助力汇锋深化鞋模产业数字化转型用数字化“点燃”鞋模领域发展引擎

The mold industry is also moving toward interconnection the advantages of digital production solutions are emerging UnionTech Joins Hands with Huifeng Shoe Molds bring professional digital solutions for the shoe mold industry,helping Huifeng deepen the digital transformation of the shoe mold industry "ignite" the development engine of the shoe mold field with digitalization

我们于2020年采购了联泰科技的十台鞋模专用3D打印机FL600HD,并且配套了Unionfab云平台管理系统。采用了联泰科技的鞋模数字化解决方案,我们的成本减少了40%, 生产效率提高了60%。至此,汇锋开启了数字化制造工艺创新新局面。 --汇锋模具生产部经理罗海军

"In 2020, we purchased ten FL600HD 3D printers dedicated to shoe mold production from UnionTech, along with the Unionfab cloud platform management system. By adopting UnionTech's digital shoe mold solution, our costs were reduced by 40%, and production efficiency increased by 60%. Thus, Huifeng has opened a new chapter in innovative digital manufacturing processes."——Luo Haijun, Production Manager of Huifeng Molds

克服挑战,传统加工模式逐渐退场

Overcoming Challenges: The Gradual Exit of Traditional Processing Models

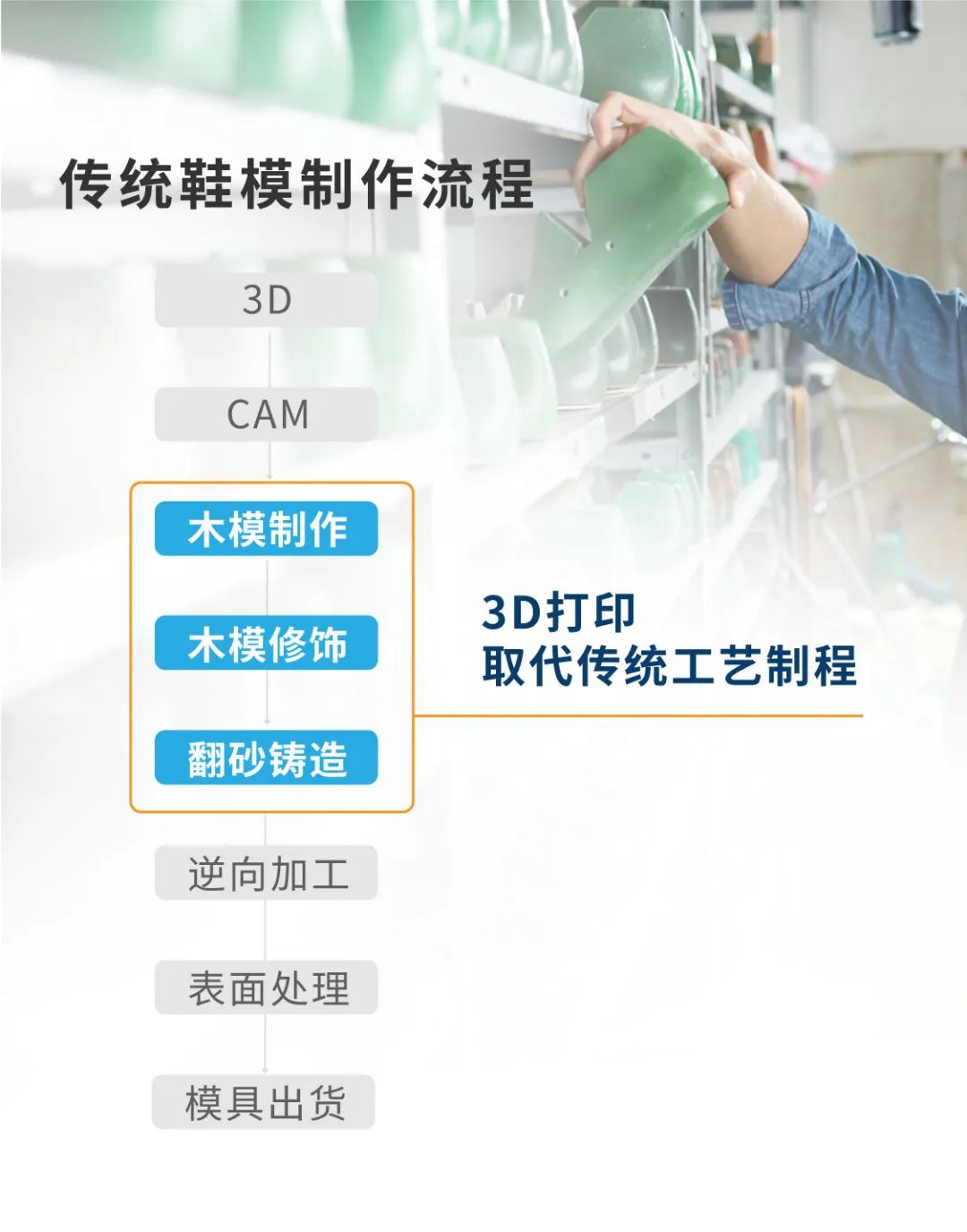

制鞋业是一个复杂的劳动密集型行业,仅是制鞋环节中的鞋底模具制造就需经历木模加工、硅胶覆模、石膏模、铸造模具、化学腐蚀咬花等多项步骤。3D打印技术为鞋制造业带来了新局面,无论是鞋模制造,还是鞋底、鞋面等鞋组件的直接制造,均能够从3D打印技术中获益,使得制造流程化繁为简,设计迭代更加高效,产品设计创新迎来更多维度。

The footwear industry is a complex labor-intensive industry. Even the manufacturing of sole molds in the shoe-making process requires multiple steps: wooden mold processing, silicone molding, plaster mold creation, casting, and chemical etching texturing.3D printing technology has brought a new phase to footwear manufacturing. Whether in shoe mold production or direct manufacturing of shoe components like soles and uppers, 3D printing simplifies manufacturing processes, enables more efficient design iterations, and introduces new dimensions for product design innovation.

传统鞋模制造流程成本高,周期长,而且精度也经常达不到理想的要求,而咬花等制造工艺中非常不环保。3D打印技术作为鞋类快速定制化生产链条中的一种重要工艺,受到了鞋类制造商的重视。3D打印为鞋制造商带来的不仅是无模具化和小批量定制化生产的能力。包括3D打印、数字化设计、三维扫描在内的数字化技术成就了鞋业模具生产小规模、去中心化的制造模式,这与传统生产模式有着质的进步。

The traditional shoe mold manufacturing process is characterized by high costs, long cycles, and frequently fails to meet ideal precision requirements. Moreover, manufacturing processes such as texturing are highly environmentally unfriendly. As a crucial technology in the rapid customization production chain of footwear, 3D printing has gained significant attention from footwear manufacturers. 3D printing not only provides shoe manufacturers with the capability of moldless production and small-batch customized manufacturing. Digital technologies including 3D printing, digital design, and 3D scanning have enabled a small-scale, decentralized manufacturing model for footwear mold production, representing a qualitative advancement compared to traditional production models.

在这种情况下,汇锋模具的生产管理团队也意识到,企业想要发展必须要改变,改变过去陈旧乏庸的传统加工制造模式。

In this context, the production management team of Huifeng Molds has also realized that for the company to develop, it must change the outdated and inefficient traditional processing and manufacturing models.

传统鞋模制造流程

Traditional Shoe Mold Manufacturing Process

锐意创新!这家鞋模厂家,实现了100%数字化制造工艺

Innovation! This Shoe Mold Manufacturer Achieves 100% Digital Manufacturing Process

汇锋模具于2020年采购了联泰科技的十台鞋模专用3D打印机FL600HD, 并且配套了Unionfab云平台管理系统。采用了联泰科技的鞋模数字化解决方案后,汇锋的成本减少了40%, 生产效率提高了60%。至此,汇锋开启了数字化制造工艺创新新局面。

In 2020, Huifeng Molds purchased ten FL600HD 3D printers dedicated to shoe mold production from UnionTech, along with the Unionfab cloud platform management system. With UnionTech's digital shoe mold solution, Huifeng reduced costs by 40% and increased production efficiency by 60%, launching a new era of innovative digital manufacturing processes.

3D打印鞋模生产铸造流程

3D Printed Shoe Mold Production and Casting Process

联泰科技鞋业事业部产品地图

UnionTech Footwear Division Product Map

3D打印技术是信息技术和数字化技术向传统制造业进行深度渗透的必然结果,脱离了传统木模的制造流程,相比之下更具智能化、自动化、高效、精准、灵活性强、综合成本低等优势。汇锋模具生产部经理罗海军表示,联泰鞋模3D打印数字化解决方案具有生产周期缩短、降低开模风险、制造成本降低、环保节能节省人力成本等众多优势。罗经理做出行业预测,他猜想未来3-5年,3D打印解决方案会全部替代传统木模加工模式。并且表示,汇锋将会关注于联泰鞋业产品的发展和布局,期待联泰在3D打印领域的新产品。

3D打印云制造SAAS平台UnionFab

3D打印云制造SAAS平台UnionFab可快速、低成本地帮助工厂完成智能升级,功能包括订单管理系统、数据助力辅助、智能排产、远程生产管理、设备数字化管理等等,快速提升企业客户服务体验、工厂生产效率、企业经营管理水平。汇锋在采用UnionFab云平台管理系统后,人力成本大大得到解放,特别是智能排产和远程生产管理的功能,深得客户赞扬。

3D Printing Cloud Manufacturing SAAS Platform UnionFab helps factories achieve intelligent upgrades quickly and at low cost. Functions include order management systems, data-assisted decision-making, intelligent scheduling, remote production management, and equipment digital management, rapidly improving customer service experience, factory production efficiency, and enterprise management levels.After adopting the UnionFab cloud platform, Huifeng significantly reduced labor costs, with particular praise for the intelligent scheduling and remote production management functions.

联泰科技凭借先进的“软件+硬件+服务”的全价值链数字化解决方案,与合作伙伴一起,完成了多个国内国外数字化行业解决方案,拥有丰富的数字化转型实践经验。

UnionTech, with its advanced "software + hardware + service" full-value-chain digital solutions, has completed multiple domestic and international digital industry solutions together with its partners, and possesses rich practical experience in digital transformation.

创新是鞭策我们进步的动力之一,我们的目标是超过客户的预期

Innovation is one of the driving forces that spur us to progress Our goal is to exceed customer expectations

创新是鞭策我们进步的动力之一,我们的目标是超过客户的预期。汇锋专注于拖鞋鞋模细分领域,在这一领域中,潜心钻研积极创新,采用先进的3D打印制造工艺,提供专业的产品和服务。

Innovation is one of the driving forces that spur us to progress, and our goal is to exceed customer expectations. Huifeng focuses on the niche field of slipper shoe molds. In this field, it dedicates itself to research, actively innovates, adopts advanced 3D printing manufacturing processes, and provides professional products and services.

--汇锋模具总经理黄列锋

联泰科技以国际化标准的产品与服务,凭借鞋业模具市场的丰富经验,帮助中国鞋模客户向高端制造企业迈进,共同见证中国数字化智能制造进程。联泰科技将持续携手行业巨擘,为客户打造一站式的3D打印解决方案,怀揣创新精神用数字化“点燃”鞋模领域发展“引擎”。

With international-standard products and services, and relying on its rich experience in the footwear mold market, UnionTech helps Chinese shoe mold customers advance towards high-end manufacturing enterprises and jointly witness the process of China's digital intelligent manufacturing. UnionTech will continue to join hands with industry giants to create one-stop 3D printing solutions for customers, and with an innovative spirit, use digitalization to "ignite" the development "engine" of the shoe mold field.

数字化将成为推动行业发展的"钥匙"联泰科技也将长期赋能数字化创新发展,提供整体解决方案,用数字化之力,解码创新与制造的未来。

Digitalization will become the "key" to driving industry development.UnionTech will also long-term empower digital innovation and development,Provide overall solutions,And use the power of digitalization To decode the future of innovation and

manufacturing.

关于汇锋

汇锋模具有限公司坐落于广东揭阳,成立于1998年,是一家集研发、生产、销售于一体的专业化制模企业,专注于拖鞋鞋模行业。公司占地面积8000多平方米,拥有现代化的标准厂房、办公大楼等。公司主营产品:吹气、水晶、双色、EVA等各种拖鞋模具,年产能达20000双以上,拥有研发、设计、3D扫描、CNC、3D打印、铸造、加工、钳工、咬花、注塑机等生产产线。

Founded in 1998 and located in Jieyang, Guangdong, Huifeng Molds Co., Ltd. is a professional mold manufacturing enterprise integrating R&D, production, and sales, specializing in slipper mold industry. The company covers an area of over 8,000 square meters, with modern standard workshops and office buildings.

Main products: various slipper molds including inflatable, crystal, two-tone, and EVA molds, with an annual production capacity of over 20,000 pairs. Production lines include R&D, design, 3D scanning, CNC, 3D printing, casting, processing, fitting, texturing, and injection molding.